Workline 610.450 DGH

This semiautomatic bandsaw is designed for both-sided mitre cuts and for cutting material up to 450 mm in diameter. The machine provides high quality at an affordable price. The excellent cutting power results from these features: a hard- metal band precision guide, an arm joint laid in slide bearings, a 34 mm high saw band, and a synchronous running brush for chips disposal. Material clamping and arm downfeed are controlled hydraulically, material feed is controlled manually.

The whole work cycle is completed at the press of the Start button: the material is clamped, the saw band starts up, cutting is carried out, the arm is raised to the default position, and the vice is opened. After switching the machine to the manual mode, all functions may be controlled separately.

Thanks to a large angle scale located within the operator’s field of vision it is easy to set the required angle precisely. The saw band speed is set on the ergonomic control panel located in the front of the machine.

The basic equipment of the machine includes a frequency convertor that allows the band’s optimal speed to be set against the processed material within the 20-120 m/min range; this significantly increases both the saw band lifetime and the machine productivity.

Standard equipment of Workline automatic machines includes automatic downfeed pressure regulation dependent on the resistance of the processed material.

Key features

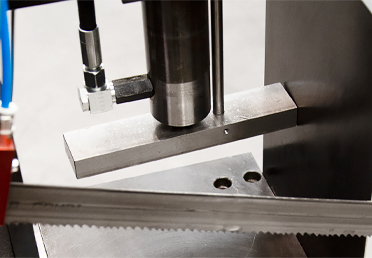

- Hardmetal saw band precision guide

- Material clamping and arm downfeed are controlled hydraulically

- Well-arranged angle scale

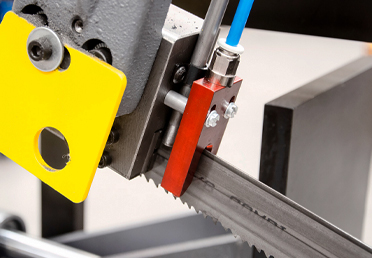

- Saw band cleaning brush

Cutting parameters

|

|

|

|

|

|

|

| 0° | 450 | 610x350 | 450 | |||

| 45°R | 450 | 480x100 | 420 | |||

| 45°L | 450 | 500x100 | 420 | |||

| 60°R | 310 | 320x100 | 300 | |||

| 60°L | 340 | 350x100 | 320 |

Technical specification

| Working mode: | semiautomatic |

| Machine type: | Horizontal bandsaw |

| Cut: | Mitre cut |

| Mitre cuts range: | -60° to +60° |

| Drive: | 3 kW, 3x400 V/50 Hz |

| Saw band speed: | 20 - 120 m/min. |

| Saw band dimensions: | 5 200x34x1,1 mm |

| Material loading height: | 781 mm |

| Shortest remnant length: | 60 mm |

Machine dimensions

| Length: | 2 781 mm |

| Width: | 1 443 mm |

| Height: | 1 564 mm |

| Weight: | 800 kg |

Suitable handling systems

Handling System T

Highly flexible handling solution for feeding medium weight materials. With the bearing capacity up to 600 kg and a wide range of accessories and connection parts of BOMAR band saws, System T is an ideal partner for handling materials in your workshop. Thanks to the default lengths of 2 and 3 m, the roller tracks are flexible and may be adjusted to any environment.

Handling System X/XP

The new X/XP handling system offers unprecedented flexibility for tailoring a handling system to individual needs and conditions. Load capacities and automation levels can be adjusted with perfect flexibility and modified at a later time. Besides the roll conveyor in a regular and propelled version, the X system comprises a rich array of options, from vertical rollers, to length measuring systems all the way to cross conveyor units and shifting devices. The load capacity can be customized by the number of rollers and support feet used. The roll conveyor's feed profile even allows varying roller and foot distances on the same roll conveyor unit. When needed, additional rollers and/or support feet can be installed at any time.

Accessories

Saw band tension indicatorThe saw band tension indicator provides permanent control of the band tension, even during the machine operation.

Saw band tension indicatorThe saw band tension indicator provides permanent control of the band tension, even during the machine operation.

Hydraulic bundle clamping device Device for clamping materials in layers and bundles with the use of an additional vertical clamping unit.

Hydraulic bundle clamping device Device for clamping materials in layers and bundles with the use of an additional vertical clamping unit.

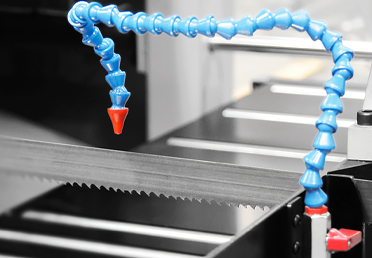

Micro-spray-systemFor ideal cutting of pipes and profiles, the micro-spray unit applies a grease film on the teeth points and lateral sides of the saw band.

Micro-spray-systemFor ideal cutting of pipes and profiles, the micro-spray unit applies a grease film on the teeth points and lateral sides of the saw band.

Laser linerThe laser unit copies the exact line in the saw band axis to the material. Laser Liner allows precise adjustment of the marked material.

Laser linerThe laser unit copies the exact line in the saw band axis to the material. Laser Liner allows precise adjustment of the marked material.

Third coolant supply The third coolant supply is used for extra wide materials. The coolant supply is flexible and may be individually adjusted to the material shape.

Third coolant supply The third coolant supply is used for extra wide materials. The coolant supply is flexible and may be individually adjusted to the material shape.

Tenzomat A precise measuring tool for the control of the saw band tension when a new band is installed.

Tenzomat A precise measuring tool for the control of the saw band tension when a new band is installed.

Digital angle indicatorFor an accurate reading angles of the arm position. Reading variables show digital display.

Digital angle indicatorFor an accurate reading angles of the arm position. Reading variables show digital display.

Pistol for machine cleaningTool for fast and easy cleaning of the machine from chips and burrs.

Pistol for machine cleaningTool for fast and easy cleaning of the machine from chips and burrs.