Ergonomic 340.278 DG

A gravity bandsaw with a robust cast-iron arm and 27 mm high saw band. The machine is equipped with a large rotary table, which is a good basis for processing short pieces of material. Table synchronously rotated with the arm and so there is no initial cut of the belt to the underlying surface. The excellent output of the machine and long lifetime of the band result from these features: a saw band precision guide, an arm joint laid in preloaded tapered bearings, and synchronous running brush for chips removal. Saw band downfeed is ensured by the arm’s self-weight. The descending speed is regulated by a hydraulic cylinder with an overflow valve. Saw arm is after cutting the lifted by hand.

The machine offers two-sided angle cuts. The machine is equipped with a frequency converter, which provides infinitely variable belt speed ranges from 20 m/min. to 120 m/min. This significantly increases blade life and productivity of the machine.

Key features

- Robust cast-iron arm

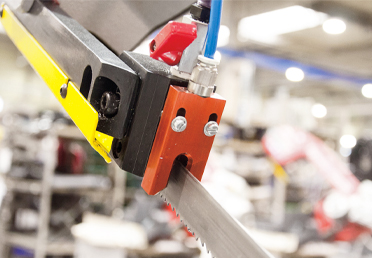

- Hardmetal band precision guide

- Quick-action vice lever

- Worm gearbox with industrial motor

Cutting parameters

|

|

|

|

| 0° | 278 | 340x100 | 275 |

| 45°R | 260 | 230x100 | 230 |

| 60°R | 155 | 145x100 | 115 |

| 45°L | 205 | 220x100 | 180 |

Technical specification

| Working mode | manual |

| Machine type | horizontal bandsaw |

| Cut | mitre cut |

| Mitre cuts range | -45° to +60° |

| Drive | 1,5 kW, 3x400 V/ 50 Hz |

| Saw band speed | 20 - 120 m/min. |

| Saw band dimensions | 3 125x25(27)x0,9 mm |

| Material loading height | 760 mm |

| Shortest remainder length | 20 mm |

| Smallest sawing diameter | Ø 5 mm |

Machine dimensions

| Length | 1 500 mm |

| Width | 1 570 mm |

| Height | 2 100 mm |

| Weight | 400 kg |

Suitable handling systems

Handling System M

Highly flexible handling solution for feeding medium weight materials. Thanks to a unique profile system, “M” System roller tracks may be easily adjusted to customer’s requirements. With the bearing capacity up to 150 kg and a wide range of accessories and connection pieces of BOMAR bandsaws, the “M” System is an ideal partner for handling material in your workshop.

Accessories

Micro-spray-systemFor ideal cutting of pipes and profiles, the micro-spray unit applies a grease film on the teeth points and lateral sides of the saw band.

Micro-spray-systemFor ideal cutting of pipes and profiles, the micro-spray unit applies a grease film on the teeth points and lateral sides of the saw band.

Laser linerThe laser unit copies the exact line in the saw band axis to the material. Laser liner allows precise adjustment of the marked material.

Laser linerThe laser unit copies the exact line in the saw band axis to the material. Laser liner allows precise adjustment of the marked material.

Additional cooling supplyAdditional coolant supply is used for extra wide materials and wherever normal cooling would not be enough.

Additional cooling supplyAdditional coolant supply is used for extra wide materials and wherever normal cooling would not be enough.

Workspace lightingA LED lamp for lighting the workspace, adjustable and mounted on the flexible arm.

Workspace lightingA LED lamp for lighting the workspace, adjustable and mounted on the flexible arm.

Tenzomat A precise measuring tool for the control of the saw band tension when a new band is installed.

Tenzomat A precise measuring tool for the control of the saw band tension when a new band is installed.

Pistol for machine cleaningTool for fast and easy cleaning of the machine from chips and burrs.

Pistol for machine cleaningTool for fast and easy cleaning of the machine from chips and burrs.