BOMAR, spol. s r.o. is a middle-sized company with its residence in Brno, Czech Republic. South Moravia and especially Brno has always been the industrial centre of Czech Republic.

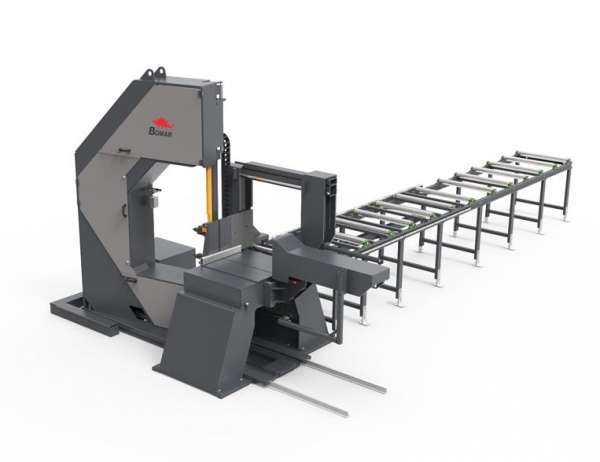

The BOMAR company has been founded in 1993, with 6 employees and 120 m2 of production area. The production schedule contained a single model of band saw – STG 200.

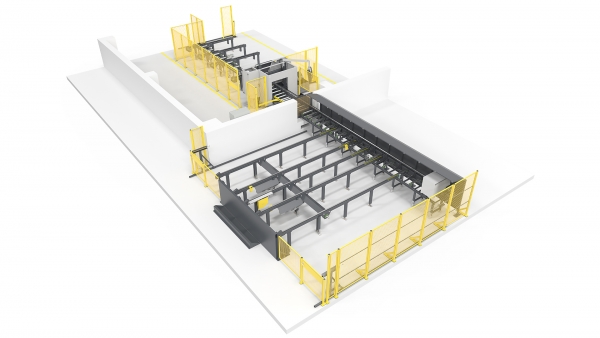

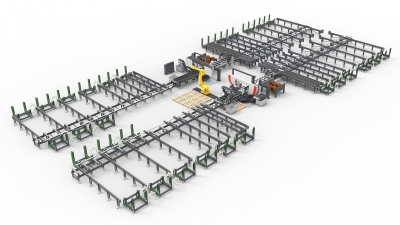

Due to strong demand for cost-effective and high-quality band saws, we were able to significantly extend the range of our products. During the following years, our company has been further expanding due to permanent development, quality improvements and extending our dealer networks in Europe, Asia and America.