ProForce 350.350 ASNC

ProForce is powerfull and automatic CNC bandsaw, prepared for high efficient productivity.

Thanks to the special construction of the machine there is the possibility to keep the highest sawing standards, even with a bimetal blade, what creates very reasonable ratio price / cut.

Machine is supposed to be a part of bigger lines and cutting centers with a combination of conveyors and cross feeding units. New and more intuitive system provides easy adjustment of the machine through dialog communication.

Already in development of each machine, we are thinking about its usefull in different conditions and in different productions. The ProForce machine is ready to be a part of a huge automatic lines for complete production processes.

You can easily extend the machine and connect the special parts as a material loading and feeding systems.

This is the way we can turn the production processes to the effective way.

Key features

- feeding controlled by a servomotor and a ball-type screw

- saw frame supported on a precise guide, pre-loaded without clearance

- automated regulation of the cutting pressure

- continuous roller track up to the main vice

Cutting parameters

|

|

|

|

|

| 0° | 350 | 350x350 | 350x350 | 350 |

Technical specification

| Working mode: | automatic |

| Machine type: | Horizontal bandsaw |

| Cut: | Straight cut |

| Mitre cuts range: | - |

| Drive: | 4 kW, 3×400 V/50 Hz |

| Saw band speed: | 20 - 120 m/min. |

| Saw band dimensions: | 5 770 x 34 x 1,1 mm |

| Material loading height: | 779 mm |

| Smallest sawing diameter: | Ø 10mm |

| Shortest remainder length: | 15 - 70 mm / 200 mm with bundle device |

Machine dimensions

| Length: | 1 390 mm |

| Width: | 2 700 mm |

| Height: | 2 110 mm |

| Weight: | 2 300 kg |

Suitable handling systems

Handling System X/XP

The new X/XP handling system offers unprecedented flexibility for tailoring a handling system to individual needs and conditions. Load capacities and automation levels can be adjusted with perfect flexibility and modified at a later time. Besides the roll conveyor in a regular and propelled version, the X system comprises a rich array of options, from vertical rollers, to length measuring systems all the way to cross conveyor units and shifting devices. The load capacity can be customized by the number of rollers and support feet used. The roll conveyor's feed profile even allows varying roller and foot distances on the same roll conveyor unit. When needed, additional rollers and/or support feet can be installed at any time.

Accessories

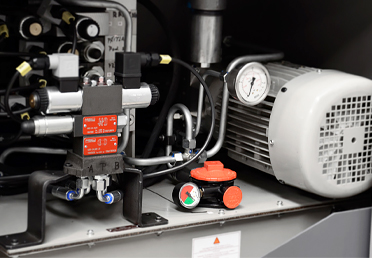

Hydraulics preheatingFor low temperatures, the hydraulic oil is heated before the saw is started, which reduces the idle time for necessary viscosity to be achieved.

Hydraulics preheatingFor low temperatures, the hydraulic oil is heated before the saw is started, which reduces the idle time for necessary viscosity to be achieved.

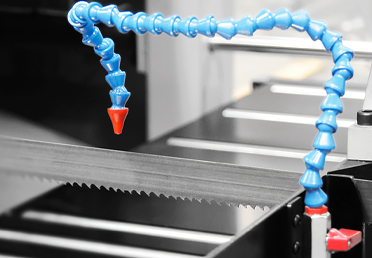

Third coolant supply The third coolant supply is used for extra wide materials. The coolant supply is flexible and may be individually adjusted to the material shape.

Third coolant supply The third coolant supply is used for extra wide materials. The coolant supply is flexible and may be individually adjusted to the material shape.

Tenzomat A precise measuring tool for the control of the saw band tension when a new band is installed.

Tenzomat A precise measuring tool for the control of the saw band tension when a new band is installed.

Remote diagnostics and maintenanceOver an Internet connection, status and error messages are transmitted to the factory and decrease downtime.

Remote diagnostics and maintenanceOver an Internet connection, status and error messages are transmitted to the factory and decrease downtime.

Pistol for machine cleaningTool for fast and easy cleaning of the machine from chips and burrs.

Pistol for machine cleaningTool for fast and easy cleaning of the machine from chips and burrs.

Swarf removal systemSwarf extractor with grabs for an integrated system of collection in Proline machines. The saw is prepared for the chip remover installation, which may be Plug-and-Play connected.

Swarf removal systemSwarf extractor with grabs for an integrated system of collection in Proline machines. The saw is prepared for the chip remover installation, which may be Plug-and-Play connected.