Extend 620.620 SX

Extend 620.620 SX is fully hydraulic semiautomatic double column band saw. The band saw is designed for cutting both full and also pro led material at an angle of 90°. The outstanding cutting power of the machine results from the following features: a three-sided hardmetal band precision guide, a saw arm laid both- sided on preloaded linear guides, a 41 mm high saw band and lastly, a synchronous running brush for chips disposal.

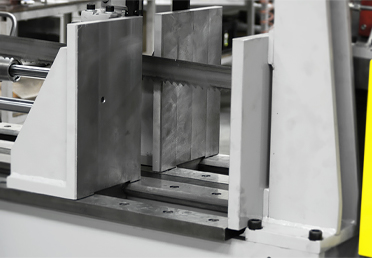

The pedestal, frame and pillars in all of the Extend Series machines are lled with a polymer-concrete mixture developed by our company. In connection with preloaded, largely over-dimensioned guiding, the polymer-concrete technology allows the machine to perform cuts with almost no vibration and with cutting speed more than 100 cm2 (with bi-metalic saw blade type M42). Clamping Vise is equipped with a large, massively dimensioned full-stroke hydraulic cylinder and can be tted by pressure control for sensitive setting maximum clamping pressure on request.

Movable clamping jaw is guided on rails hardened wear resistant. The machine is equipped with a frequency converter, which enables to set the optimum speed of the blade in the range from 15 to 90 m / min. This significantly increases both blade life and machine productivity.

Extend SX Series machines deliver innovative controls that allow seamless expansion functions with regard to the customer’s requirements. This means that the Extend SX machines are ideal for customized cutting lines.

The machine can be used in semi-automatic mode, but also machine can be switched to manual mode where all functions of the machine may be controlled separately. Machine control is provided by simple text messages on large LCD. Display is placed on the freely- adjustable control panel. The standard equipment also includes automatic downfeed pressure regulation dependent on the resistance of the processed material, and continuously adjustable arm downfeed.

The saw band is tilted against the vice load surface at a 2° angle for universal usage. Upon request, the arm may be tilted at 6° for an even shorter cutting groove in pro les and supports which substantially shortens cutting times and contributes to a longer lifetime of the saw band. Alternatively, the arm need not be tilted at all (0°) for processing full material.

Key features

- Two-column structure

- Hydraulic full-lift clamping vice

- Continuously adjustable saw arm feed to depth and pressure to depth

- Freely positionable control panel

Cutting parameters

|

|

|

|

|

|

|

| 0° | 620 | 620x620 | 620 |

Technical specification

| Working mode: | automatic |

| Machine type: | Horizontal bandsaw |

| Cut: | Straight cut |

| Mitre cuts range: | - |

| Drive: | 7,5 kW, 3×400 V/50 Hz |

| Saw band speed: | 15 – 90 m/min. |

| Saw band dimensions: | 7 580×54×1,6 mm |

| Material loading height: | 780 mm |

| Shortest remainder length: | 30 mm |

| Smallest sawing diameter: | - |

Machine dimension

| Length: | 3 600 mm |

| Width: | 1 260 mm |

| Height: | 2 400 mm |

| Weight: | 4 000 kg |

Suitable handling systems

Handling System X/XP

The new X/XP handling system offers unprecedented flexibility for tailoring a handling system to individual needs and conditions. Load capacities and automation levels can be adjusted with perfect flexibility and modified at a later time. Besides the roll conveyor in a regular and propelled version, the X system comprises a rich array of options, from vertical rollers, to length measuring systems all the way to cross conveyor units and shifting devices. The load capacity can be customized by the number of rollers and support feet used. The roll conveyor's feed profile even allows varying roller and foot distances on the same roll conveyor unit. When needed, additional rollers and/or support feet can be installed at any time.

Accessories

Saw band tension indicatorThe saw band tension indicator provides permanent control of the band tension, even during the machine operation.

Saw band tension indicatorThe saw band tension indicator provides permanent control of the band tension, even during the machine operation.

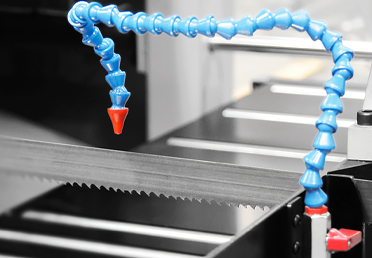

Micro-spray-systemFor ideal cutting of pipes and profiles, the micro-spray unit applies a grease film on the teeth points and lateral sides of the saw band.

Micro-spray-systemFor ideal cutting of pipes and profiles, the micro-spray unit applies a grease film on the teeth points and lateral sides of the saw band.

Hydraulic bundle clamping device Device for clamping materials in layers and bundles with the use of an additional vertical clamping unit.

Hydraulic bundle clamping device Device for clamping materials in layers and bundles with the use of an additional vertical clamping unit.

Downfeed speed readoutAllows easy and accurate reading of the current rate of descent of the machine arm into the cut.

Downfeed speed readoutAllows easy and accurate reading of the current rate of descent of the machine arm into the cut.

Additional vice Divided clamping device with hardened inlays and a full-lift cylinder for tensioning before and after the saw blade.

Additional vice Divided clamping device with hardened inlays and a full-lift cylinder for tensioning before and after the saw blade.

Laser linerThe laser unit copies the exact line in the saw band axis to the material. Laser Liner allows precise adjustment of the marked material.

Laser linerThe laser unit copies the exact line in the saw band axis to the material. Laser Liner allows precise adjustment of the marked material.

Workspace lightingA LED lamp for lighting the workspace, adjustable and mounted on the flexible arm.

Workspace lightingA LED lamp for lighting the workspace, adjustable and mounted on the flexible arm.

Third coolant supply The third coolant supply is used for extra wide materials. The coolant supply is flexible and may be individually adjusted to the material shape.

Third coolant supply The third coolant supply is used for extra wide materials. The coolant supply is flexible and may be individually adjusted to the material shape.

Tenzomat A precise measuring tool for the control of the saw band tension when a new band is installed.

Tenzomat A precise measuring tool for the control of the saw band tension when a new band is installed.

Pistol for machine cleaningTool for fast and easy cleaning of the machine from chips and burrs.

Pistol for machine cleaningTool for fast and easy cleaning of the machine from chips and burrs.

Swarf removal systemSwarf extractor with grabs for an integrated system of collection in Proline machines. The saw is prepared for the chip remover installation, which may be Plug-and-Play connected.

Swarf removal systemSwarf extractor with grabs for an integrated system of collection in Proline machines. The saw is prepared for the chip remover installation, which may be Plug-and-Play connected.